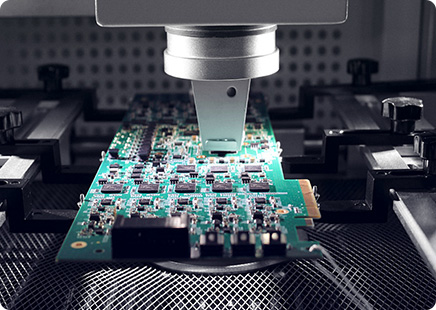

Fine pitch placement up to 12 mil

Component ranges from 01005 BGA and uBGA, CSP up to 55 mm sq

±25 micron placement accuracy with 3-Sigma capability

Board size: 534 x 610 mm

Board types: Rigid, Flex, Ceramic Substrate

SMT assembly in a class and dust-free zone

N2-enabled reflow soldering machines to produce high reliable solder joints

End-to-end traceability systems

Through-hole component assembly and dedicated product assembly line for volume builds

End-to-end traceability systems

Screen printers – MPM Accuflex

Placement machines – Fuji, Universal, Yamaha

SPI Machines – Cyber Optics, KY 3020T

Reflow ovens – Electrovert, Heller

AOI – Cyber Optics, Agilent, Viscom, KY, Vitrox

Router/depanelizer (manual & automatic systems)

Traceability software – Fuji Trax

Conformal coating and UV check chambers

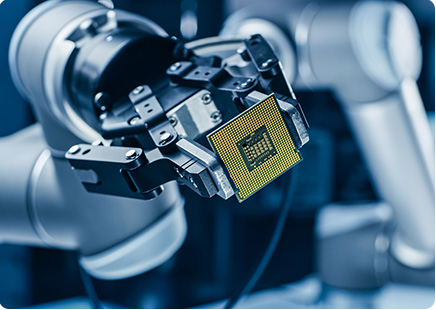

BGA repair station

In Circuit Testers – Kyoritsu, Tescon

Manufacturing Defect Analyzers – TRI

3D X-ray Inspection Systems

Customized automated test equipment

Environment & thermal shock chamber

Coordinate measuring machine – Mitutoyo

Profile projector (125Khz LCR meter)

Solder paste viscosity meter & height measurement

Video measuring machine

Vibration & bump tester